Maintenance Optimisation

|

|

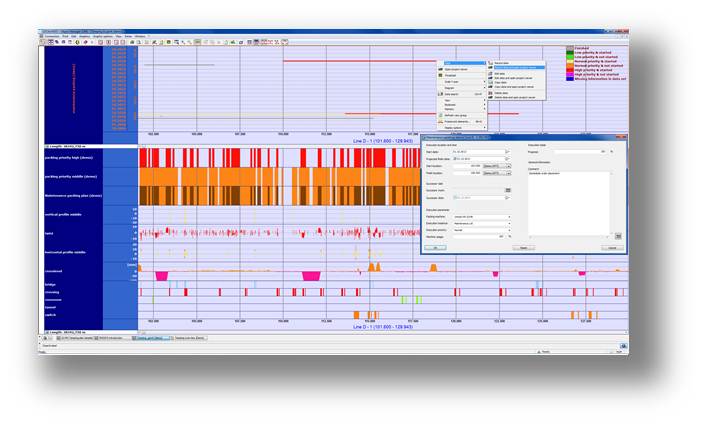

The correct distribution of severely limited funds is the vital maintenance problem. In reality, a maintenance strategy designed for a minimum of costs at short notice is tracked in many cases. Using the integrated status analysis that understands the track as a complex system with interactions among the system elements, you can define the correct priorities and distribute funds in an optimal manner. The resulting scheduled preventive maintenance assures an approach to the minimum of total cost as well as a long track service life. |

|

|---|---|---|

|

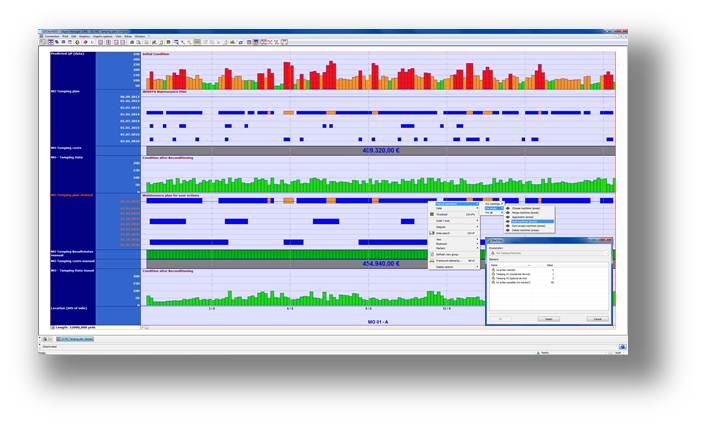

Basing on previously developed prediction scenarios, it is possible to automatically generate maintenance proposals with the aid of the maintenance optimisation in IRISSYS®. For this, you can parameterize various parameters for maintenance machines to be used, as e.g. cost, effect, and the rate of maintenance works. Further criteria, such as thresholds as well as intervals and deadlines for the optimisation, can be passed to the optimisation procedure as well. |

||

|

After that, you can manually rework the system proposals according to specific railway aspects. Then these two variants can be compared in the same diagram. These way individual requirements of the parties responsible are considered. Finally both variants can be compared in the same diagram in respect to their effect and cost, in which IRISSYS® provides assistance with its mathematically optimised solution. |